Industrial heat treatment furnaces are essential equipment used to alter the physical and mechanical properties of metals through controlled heating and cooling processes. These furnaces come in various types, each designed to meet specific treatment goals such as hardening, annealing, tempering, and surface carburizing. Selection of the right furnace depends on factors like material type, part geometry, load capacity, and required thermal cycle. There are several types of heat treatment furnaces from batch-operated box and pit furnaces to continuous systems like roller hearth and belt furnaces, each type offers unique advantages in terms of precision, energy efficiency, and production throughput across various manufacturing sectors.

1. Types of Heat Treatment Furnaces Based on Design and Application

| Furnace Type | Description | Common Applications |

|---|---|---|

| Box Furnace | A fixed, rectangular chamber. Charge is loaded from the front. | General heat treatment, annealing, tempering |

| Pit Furnace | Vertical design, material is lowered into the chamber. | Annealing of shafts, long bars, and cylindrical parts |

| Bogie Hearth Furnace | Movable hearth (bogie) rolls in and out; suitable for heavy loads. | Forgings, castings, dies, large components |

| Bell Furnace | Removable dome (bell) lowered over the workload on a fixed base. | Bright annealing, batch processing with atmosphere control |

| Car Bottom Furnace | Similar to bogie hearth but for extremely heavy/large loads. | Steel and alloy treatment in foundries |

| Muffle Furnace | Heating elements are separated from the chamber by a muffle. | Laboratory and small-scale precise heat treatment |

| Rotary Hearth Furnace | Rotating hearth for uniform heating, fast loading/unloading. | Case hardening, gear parts, fasteners |

| Roller Hearth Furnace | Charge moves continuously over rollers through heated zones. | Mass production of plates, sheets, or slabs |

| Walking Beam Furnace | Load is lifted and advanced using walking beams. | Steel reheating in rolling mills |

| Continuous Belt Furnace | Mesh belt or solid belt carries material continuously. | Sintering, brazing, small part heat treatment |

| Elevator Furnace | Base moves vertically for loading/unloading. | Batch-type heat treatment where space is a concern |

| Fluidized Bed Furnace | Uses fluidized particles as heat transfer medium. | Quenching, heat treating with uniform heating |

| Vacuum Furnace | Operates under vacuum for oxidation-free treatment. | Tool steels, aerospace parts, brazing |

2. Types of Furnaces Based on Heat Treatment Process

| Process Type | Furnace Type Used | Typical Treatment Purpose |

|---|---|---|

| Annealing | Box, Pit, Bell, Car Bottom | Soften metals, improve ductility |

| Tempering | Box, Conveyor, Bell | Reduce brittleness after hardening |

| Hardening/Quenching | Bogie Hearth, Pit, Batch Furnaces with oil or water quench tanks | Increase strength/hardness |

| Normalizing | Box, Car Bottom | Refine grain structure, uniform mechanical properties |

| Carburizing/Nitriding | Sealed Quench, Pit, Bell | Surface hardening (gas/atmosphere control) |

| Brazing/Sintering | Continuous Belt, Vacuum, Muffle, Controlled Atmosphere | Joining/sintering metal powders or parts |

| Solution Annealing | Pit, Box, Bogie Hearth, often followed by water quench | Stainless steels and alloys |

| Aging/Precipitation | Box, Conveyor | Strengthen aluminum and titanium alloys |

| Stress Relieving | Box, Pit, Bell | Remove residual stresses after machining/welding |

| Cryogenic Treatment | Separate from furnace; involves sub-zero cooling | Enhance wear resistance, dimensional stability |

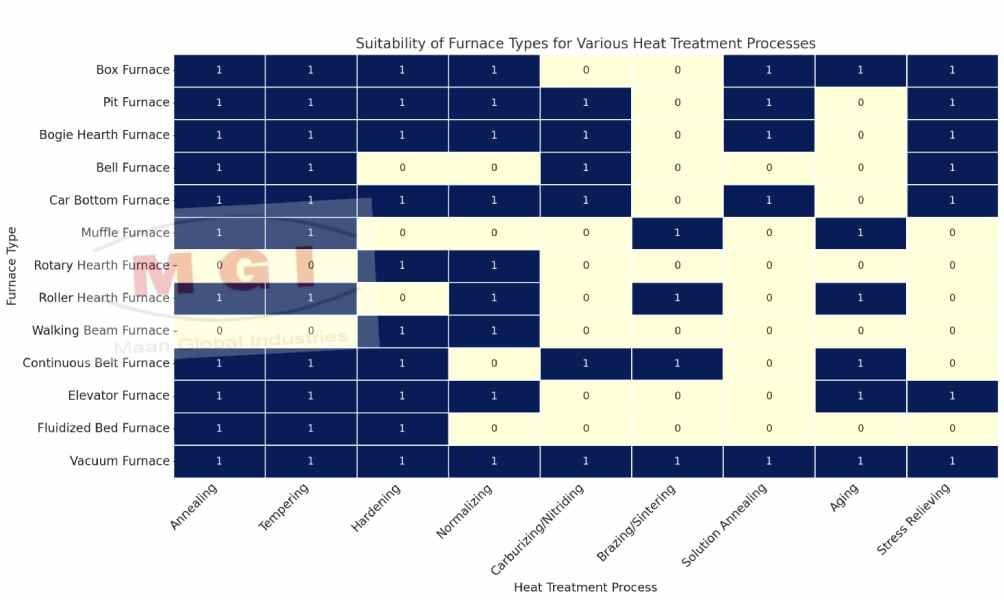

Suitability of Furnaces for Various Types of Industrial Heat Treatment Processes

Technical Guide for Selecting the Heat Treatment Right Furnace for your Application

| Application | Recommended Furnace Type(s) | Reason |

|---|---|---|

| General Heat Treatment (Steel, Alloy) | Box, Pit, Bogie Hearth | Versatile, supports various batch processes |

| Long Shafts, Bars, Cylindrical Parts | Pit Furnace | Vertical loading, uniform treatment over length |

| Heavy Forgings, Large Dies | Bogie Hearth, Car Bottom | Heavy-duty loading, large space, easy material handling |

| Bright Annealing/Controlled Atmosphere | Bell Furnace, Vacuum Furnace | Sealed chamber, precise atmosphere control |

| Tool Steels, Aerospace Parts | Vacuum Furnace | Oxidation-free, precise temperature profiles |

| Mass Production of Plates/Sheets | Roller Hearth, Walking Beam | Continuous processing, energy-efficient |

| Surface Hardening (Carburizing/Nitriding) | Pit, Sealed Quench, Bell | Atmosphere-controlled and deep case hardening |

| Brazing/Sintering (Metals/Powders) | Vacuum, Muffle, Continuous Belt | Uniform temperature, protective atmospheres |

| Aluminum Solution Annealing | Pit, Box, Bogie Hearth | Suitable for water quench after annealing |

| Aging (Aluminum, Titanium Alloys) | Box, Conveyor | Controlled time-temperature cycle |

| Stress Relieving (Post-Weld/Machining) | Box, Bell, Pit | Slow heating and cooling prevents distortion |

| Precision Small Parts/Lab Use | Muffle, Elevator | Compact and energy-efficient |

Batch-Type Heat Treatment Furnaces

Industrial heat treatment relies on various types of furnaces tailored to specific metallurgical requirements and production capacities.

Among batch-type systems, box furnaces are the most versatile, with a rectangular chamber where parts are loaded manually or by crane. These are used for annealing, stress relieving, hardening, and tempering of steels and alloys.

Pit furnaces, on the other hand, feature a vertical loading chamber, making them ideal for long cylindrical parts like shafts, pipes, or bars. Their design ensures uniform heating over the length of the component, especially useful for annealing and carburizing.

Bogie hearth furnaces (also known as car-bottom furnaces) include a movable trolley or hearth on rails that transports heavy components in and out of the heating chamber. These are essential for large forgings, dies, and castings, where high mass and volume are involved.

Bell furnaces use a removable dome that is lowered onto a stationary base containing the load. These are highly suitable for controlled atmosphere processes like bright annealing, where oxidation must be avoided.

Muffle furnaces, often used in labs or for small components, have an internal chamber isolated from direct flame or heating elements, ensuring precise and contamination-free heating.

Another specialized design is the vacuum furnace, which operates under low pressure or vacuum, eliminating oxidation during heat treatment. It is widely used for tool steels, aerospace components, and high-precision parts requiring ultra-clean surfaces.

These batch furnaces provide flexibility, precise temperature control, and are ideal for small-to-medium scale or custom treatments, though they can be less efficient for high-throughput production. Their design varies from simple manual systems to highly automated, atmosphere-controlled models. The choice of furnace depends on load size, treatment type, desired mechanical properties, and metallurgical considerations such as oxidation, case hardening depth, or material phase changes.

Continuous and Specialized Heat Treatment Furnaces

For high-volume, consistent heat treatment, continuous and specialized furnaces play a crucial role in modern manufacturing.

Roller hearth furnaces use a series of rollers to carry workpieces through a heated tunnel, enabling efficient processing of sheets, slabs, and other flat components. These furnaces are highly favored in steel mills and automotive manufacturing lines for processes like normalizing or stress relieving.

Rotary hearth furnaces, featuring a rotating circular platform, are suitable for case hardening, forging, and carbonitriding of parts like gears, bearings, and fasteners. The rotation ensures uniform exposure and heating, while quick loading/unloading improves productivity.

Walking beam furnaces lift and advance materials step-by-step using hydraulic or mechanical beams, commonly found in billet or bloom reheating before hot rolling. Their precision and scalability make them ideal for heavy-duty operations.

Continuous belt furnaces, often called mesh belt furnaces, convey small parts on a metal belt through various temperature zones, including preheat, soak, and cooling sections. These are widely used in brazing, sintering, and carbonitriding processes, especially in fastener and component manufacturing.

Fluidized bed furnaces offer uniform heat transfer by suspending fine solid particles using gas flow. This design provides excellent heat uniformity and rapid heat-up rates, ideal for quenching and carburizing.

Elevator furnaces are used in compact spaces, where the entire load is raised or lowered into the furnace, suitable for precise small batch processes.

Atmosphere-controlled furnaces, like sealed quench furnaces, are essential for gas carburizing, nitriding, and bright annealing processes, ensuring surface integrity and controlled case depth. These continuous or semi-continuous systems are favored for their automation potential, consistent quality, and energy efficiency. Selecting the right furnace requires matching the heat treatment cycle, material type, part geometry, and production throughput for optimal metallurgical and economic outcomes.

Industrial Furnace Manufacturer Saudi Arabia

UAE Industrial Furnace Manufacturers

Salt Bath Furnace Manufacturer

Bogie Hearth Furnace Manufacturer

Carburizing Furnace Manufacturer

Pulse Jet Dust Collector Manufacturer

Kuwait Industrial furnace manufacturer

Industrial Chiller Manufacturer

Post Weld Stress Relief Heat Treatment

Composite Drying Oven Manufacturer

Plastic Annealing Oven Manufacturer

Motor Drying Oven Manufacturer

Die Pre Heating Oven Manufacturer

Xylan Coating Oven Manufacturer

Annealing Heat Treatment Process Guide

Cyclone Dust Collector Manufacturer

Aluminum Melting Furnace Manufacturer

Aluminum Heat Treatment Furnace Manufacturers

Powder Coating Plant Manufacturer

MAAN GLOBAL INDUSTRIES is the leading Industrial Heat Treatment Furnace manufacturer in India. Our engineers design and manufacture wide range of industrial heat treatment furnaces based on the application requirements and heat treatment process. We manufacture Electric Pit furnaces and Gas fired Pit furnaces that are inert atmosphere capable and carry batch load of up to 20 tons. We are the pioneers in Heat Treatment Furnace Manufacturing in India. Top industrial Furnace Suppliers in Africa, Oman, Kuwait, Dubai, Kenya, Uganda, Europe, Indonesia, Malaysia, Australia and Sri Lanka.

https://www.azom.com/article.aspx?ArticleID=22906

https://www.iqsdirectory.com/articles/furnace/types-of-industrial-furnaces.html