Heat exchangers play a vital role in various industrial processes, facilitating the transfer of heat between two fluids without mixing. Among the diverse types of heat exchangers, the double pipe heat exchanger stands out for its simplicity, flexibility, and efficient heat transfer capabilities. In this article, we will delve into the key aspects of double pipe heat exchangers, their specifications, types, advantages, disadvantages, design considerations, and applications. After determination of the required heat transfer surface area and other technical aspects with reference to the process application, a double pipe heat exchanger manufacturer would design and fabricate the heat exchanger system. We Maan Global Industries, manufacturer of double pipe heat exchangers in India provide high and international quality standards double pipe heating system. We use high quality raw material in the development of double pipe heat exchangers. Since, 2006, Maan Global Industries backed by it’s experience in thermal process engineering has become a prominent double pipe heat exchanger manufacturer in India with over 5000 installations.

This type of heat exchangers are mostly used in the fields of Thermal Power Station, petroleum and Heat Industry, Oil and food Plants, Power Stations and etc.

Understanding Double Pipe Heat Exchangers:

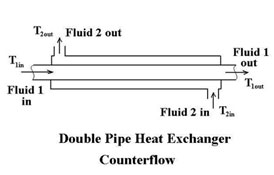

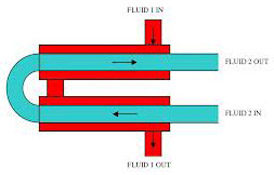

A double pipe heat exchanger comprises two concentric pipes separated by a mechanical closure. This design allows for the efficient transfer of heat between fluids without direct contact. The inner pipe acts as a conductive barrier, with one fluid flowing through its interior and another in the annular space between the two pipes.

The simplicity of the double pipe heat exchanger design makes it a versatile choice for various applications. It is known by different names such as hairpin, jacketed pipe, jacketed u-tube, and pipe in pipe exchanger. The outer pipe’s diameter must be less than 200mm, and it can contain a single pipe or a bundle of pipes (usually fewer than 30). Longitudinal fins may be incorporated in the inner tube to enhance heat transfer rates. A Double pipe heat exchanger manufacturer plays a crucial role in providing efficient and reliable heat transfer solutions for various industries. These specialized manufacturers are dedicated to designing, fabricating, and delivering high-quality double pipe heat exchangers tailored to the unique requirements of their clients. The expertise of a double pipe heat exchanger manufacturer in Mumbai ensures that the heat exchangers meet stringent industry standards, providing optimal performance in diverse applications.

Double Pipe Heat Exchanger Basics Explained

Specification and Applications:

Double pipe heat exchangers are characterized by their straightforward design, making them suitable for low-capacity applications where the heat transfer area is less than 45 square meters. Consideration of fluid types is crucial, with viscous fluids recommended for the shell side due to the increased available space for flow.

When choosing a double pipe heat exchanger, project specifications, including inlet and outlet temperatures, and required heat transfer rates, should be defined. The design is modular and simple, but an increase in surface area results in higher costs. When selecting a double pipe heat exchanger manufacturer in India, it is essential to consider their experience, reputation, and commitment to quality. Established manufacturers bring a wealth of knowledge and technical expertise to the table, ensuring that the heat exchangers are not only well-crafted but also adhere to industry-specific regulations. Reputable heat exchanger manufacturers in Maharashtra often invest in advanced technologies and employ skilled engineers to design and produce heat exchangers that deliver efficient heat transfer while maximizing durability.

Types of Double Pipe Heat Exchangers:

Double pipe heat exchangers can be categorized based on flow direction, with counter flow and parallel flow being the two main types. The choice between these types impacts heat transfer efficiency and pressure drop in the system.

-

Counter Flow Double Pipe Heat Exchangers: Counter flow design is considered optimal for double pipe heat exchangers. In this configuration, fluid flows in opposite directions, maximizing the heat transfer coefficient. The temperature difference between fluids is highest at both ends, allowing for effective heating or cooling.

-

Parallel Flow Double Pipe Heat Exchangers: In parallel flow, both inlets and outlets are on one head. While less efficient than counter flow, parallel flow is suitable for specific applications.

Customers seeking double pipe heat exchangers can benefit from the extensive range of options provided by reputable manufacturers. These options may include variations in size, materials of construction, and specific design features tailored to meet the demands of various applications. The collaboration between customers and a double pipe heat exchanger manufacturer in Pune is crucial in ensuring that the final product aligns with the unique specifications and operational requirements of the intended heat transfer system.

Product Specification of Double Pipe Heat Exchanger

| Type of Heat Exchanger | Double Pipe Heat Exchanger |

| Usage/Application | Industrial, Pharmaceutical, Chemical, Water Treatment, Distillery |

| Brand | Maan Global Industries |

| Flow Rate | 5 m/s |

| Material | Stainless Steel |

| Steel Grade | SS304 |

| Frequency | 50 Hz |

| Surface Finish | Polished |

| Price | Rs. 5,50,000 Lacs |

| Voltage | 240 V |

| Country of Origin | Made in India |

Polished SS Double Pipe Heat Exchanger

| Type of Heat Exchanger | Polished Double Pipe Heat Exchanger |

| Usage/Application | Industrial, Pharmaceutical, Chemical, Water Treatment, Distillery |

| Brand | Maan Global Industries |

| Flow Rate | 2 m/s |

| Material | Stainless Steel |

| Steel Grade | SS304 |

| Frequency | 50 Hz |

| Surface Finish | Polished |

| Price | Rs. 4,50,000 Lacs |

| Voltage | 240 V |

| Country of Origin | Made in India |

Double Pipe Heat Exchanger Manufacturer in India – Maan Global Industries

Advantages and Disadvantages:

Double pipe heat exchangers come with distinct advantages and disadvantages, making them suitable for certain applications:

Advantages:

-

Cost-Effective Efficiency:

- Provides good efficiency with lower capital costs.

- Compact design requires minimal space for maintenance.

-

Standardized Parts:

- All components are standardized, facilitating easy repairs and maintenance.

-

Flexible Design:

- Easily adaptable with the addition or removal of parts.

-

High-Pressure and Temperature:

- Suitable for applications with high pressure and temperature requirements.

-

Thermal Expansion:

- Allows for more thermal expansion without the need for expansion joints.

Disadvantages:

-

Limited Heat Transfer:

- Not suitable for high heat duty applications due to limitations in heat transfer.

-

Leaking:

- More prone to leaking, particularly with an increased number of units.

Design Principle:

Designing a double pipe heat exchanger involves considering specifications and demands to determine the required heat transfer area. The heat transfer equation, Q=UAΔTlm, where Q is the heat transfer rate, U is the heat transfer coefficient, A is the surface area, and ΔTlm is the log mean temperature difference, guides the design process.

Characteristics of Double Pipe Heat Exchangers:

- Made up of concentric pipes with mechanical closures.

- Suited for high-temperature, high-pressure applications.

- Inexpensive, durable, and easy to maintain.

- Simple construction.

Conclusion:

In conclusion, double pipe heat exchangers stand as a testament to efficiency through simplicity. With a design that allows for versatility, ease of maintenance, and suitability for various applications, they remain a preferred choice for many projects. Understanding their advantages, disadvantages, and design considerations provides valuable insights for engineers and industries seeking effective heat transfer solutions in high-temperature and high-pressure environments. The importance of choosing a reliable double pipe heat exchanger manufacturer in India, cannot be overstated. These manufacturers play a pivotal role in providing cutting-edge solutions for industries requiring efficient heat transfer. Whether for applications in the chemical, petrochemical, or manufacturing sectors, partnering with reputable manufacturers ensures the delivery of high-performance double pipe heat exchangers designed to meet the diverse needs of modern industrial processes.

If you are looking for a Double Pipe Heat Exchanger Manufacturer in India or a Shell Tube Heat Exchanger Manufacturer in Mumbai, Delhi, Pune, Hyderabad, Kolkata, Bangalore, Chennai then Call: 8882490101 or fill out the form on the right.

Shell Tube Heat Exchanger Manufacturer

Hot Air Generator Manufacturer

Kuwait Industrial furnace manufacturer

Motor Drying Oven Manufacturer

High Temperature Furnace Manufacturers

Industrial Furnace Manufacturer Saudi Arabia

Bogie Hearth Furnace Manufacturer

Industrial Furnace Prices in India

Aluminum Heat Treatment Furnace Manufacturers

Aluminum Melting Furnace Manufacturer

Food Dryer Dehydrator Manufacturer

Heat Treatment Furnace Installations

Plastic Annealing Oven Manufacturer

Carburizing Furnace Manufacturer

Post Weld Stress Relief Heat Treatment

Air compressor Manufacturer Supplier

Annealing Normalizing Furnace Manufacturer

References:

https://www.thermopedia.com/content/705/

https://web.iitd.ac.in/~pmvs/courses/mel709/classification-hx.pdf