In modern manufacturing, surface preparation plays a critical role in the durability and performance of powder-coated components. The 7 tank pre-treatment phosphating process is one of the most reliable and efficient solutions for cleaning and preparing metal surfaces such as mild steel, GI, and aluminum prior to coating. As a trusted 7 tank phosphating plant manufacturer India, Africa, Sharjah, Dubai, Kenya, we specialize in building robust, customizable pre-treatment lines for industries such as panel manufacturing, fabricated structures, enclosures, auto parts, and engineering components. Our systems are engineered to deliver optimal phosphate or silane coating on a variety of metal substrates while complying with global standards.

Overview of the 7 Tank Phosphating Process

Table of Contents

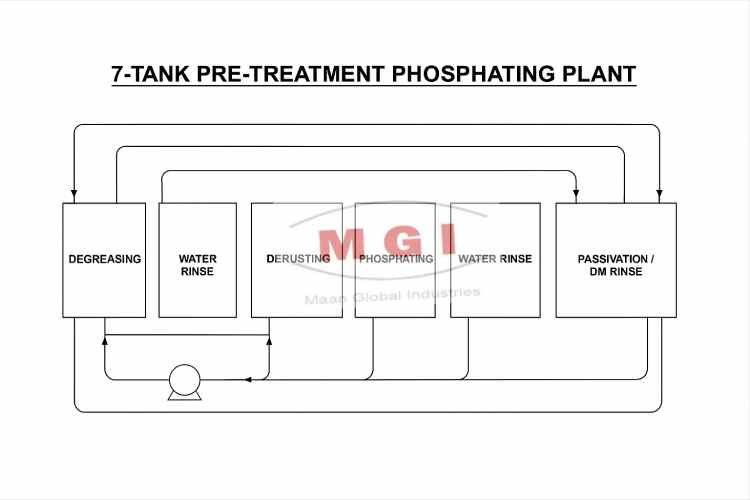

The 7 tank process typically includes:

-

Degreasing Tank – For removing oil and contaminants

-

Water Rinse 1 – To flush alkaline residues

-

Water Rinse 2 – Final rinse before acid pickling

-

Derusting / Pickling – Removes rust and scale

-

Phosphating or Silane Conversion Coating – Micro-crystalline phosphate coating

-

Water Rinse 3 – Rinse to remove unreacted chemicals

-

Final DM Rinse or Passivation – Enhances corrosion resistance

System Components and Construction Details

| Component | Description |

|---|---|

| Tanks | Sizes: 3500 × 1400 × 1800 mm Materials: FRP-lined MS, SS 304/316, HDPE |

| Heating System | Immersion heaters or coil-based heating for degreasing and phosphating tanks |

| Dosing Pumps | Precise chemical control, with pH sensors and metering systems |

| Bag Filters | 25 µm polypropylene filtration for Silane and rinse tanks |

| Crane System | Manual or motorized hoists with SS cradle for batch handling |

| DM Water System | 500–1000 LPH RO + DM plant for conductivity <30 µS/cm |

| Exhaust/Vapor Control | PVC ducts, PP scrubbers for acid mist suppression |

Each tank and component is chosen based on its compatibility with the chemical used, the process temperature, and required throughput. Our systems are also designed for integration with ETPs, mist eliminators, and PLC-based auto dosing panels.

7 Tank Phosphating Plant Manufacturer India

India remains one of the largest markets for powder-coated sheet metal and structural components. As a dependable 7 tank phosphating plant manufacturing company India, Africa, Kenya, Dubai, Sharjah, South Africa, we supply tailored immersion-type lines to manufacturers in Pune, Mumbai, Nashik, Coimbatore, Hyderabad, Kolkata and more. Built for high throughput, our plants include custom-sized tanks, motorized crane handling, and Oxsilan or phosphate compatibility. Being a top-rated 7 tank phosphating plant manufacturer India, Africa, Kenya, Dubai, Sharjah, South Africa, we also offer water treatment plant like DM water Plant and RO plant.

7 Tank Phosphating Plant Manufacturer Africa

As an experienced 7 tank phosphating plant manufacturing company Africa, we deliver rugged and modular pre-treatment plants to support industries across Nigeria, Ethiopia, Ghana, and Egypt. Our systems are specifically built to handle variable water quality and harsh conditions. Designed with locally serviceable components, our plants integrate overflow rinsing, DM water reusability, and bag filters for chemical longevity. With support from our India-based design team, customers benefit from layout customization, startup supervision, and hands-on chemical training from one of the most reliable 7 tank phosphating plant manufacturer Africa.

7 Tank Phosphating Plant Manufacturer Kenya

Kenya’s growing demand for electrical enclosures, switchboards, and fabricated steel products has increased the need for reliable surface treatment systems. As a leading 7 tank phosphating plant manufacturer Kenya, we provide turnkey pre-treatment lines designed for manual or semi-automatic coating plants. Our systems feature FRP-lined tanks, optional automated dosing, and low-TDS DM rinse configurations. Trusted as a 7 tank phosphating plant manufacturing company Kenya, we ensure technical documentation, SOPs, and remote troubleshooting support are provided to all clients.

7 Tank Phosphating Plant Manufacturer South Africa

South Africa’s automotive, electrical, and utility sectors heavily rely on long-lasting powder-coated steel. As a reputable 7 tank phosphating plant manufacturer South Africa, we offer complete immersion-type systems built for rugged industrial applications. Our tanks are constructed using SS 316 or chemically resistant FRP, while all heating and dosing systems are integrated with local voltage compatibility. Designed for compliance with SANS 1091 and ISO 1461 standards, our lines are used by panel builders and structural fabricators across Johannesburg, Durban, and Cape Town. As a go-to 7 tank phosphating plant manufacturing company South Africa, we also support logistics, site preparation, and spares availability through regional agents.

7 Tank Phosphating Plant Manufacturer Sharjah

Sharjah’s industrial zones require compact and compliant surface treatment lines. As a certified 7 tank phosphating plant manufacturer Sharjah, we supply efficient and safe immersion plants with acid-proof flooring support, PVC ducting, and fume scrubber integration. With limited space and strict environmental norms, our systems are built to include chemical containment trays, automatic level controllers, and air blow-off zones. Recognized as a compliant 7 tank phosphating plant manufacturing company Sharjah, we ensure adherence to EHS and Civil Defense regulations.

7 Tank Phosphating Plant Manufacturer Dubai

Dubai-based fabricators working in oil & gas, solar, and infrastructure sectors need international-grade phosphating plants. As a well-regarded 7 tank phosphating plant manufacturer Dubai, we deliver semi-automated lines with touch-screen PLC interfaces, dosing control, and high-purity zinc phosphate/silane conversion tanks. Our projects in Jebel Ali, Dubai Industrial City, and DIP are known for operational safety and high coating consistency. We are a registered 7 tank phosphating plant manufacturing company Dubai, delivering containerized systems, on-site commissioning, and after-sales support across the UAE.

Industrial Use Cases

-

Electrical Panel Boxes

-

Solar Mounting Structures

-

GI Enclosures and Cabinets

-

Engine Frames and Housings

-

Street Furniture and Poles

-

Metal Fabrication Shops

Why Choose MAAN GLOBAL INDUSTRIES, a Leading Phosphating Plant Manufacturer in India

-

15+ years as a global 7 tank phosphating plant manufacturer India

-

Pre-engineered and custom layouts

-

International support teams for Africa and the Middle East

-

Post-installation service contracts and process audits

Contact Us

Contact India: mail@maanglobalindustries.com or fill out the form on the right

International: export@maanglobalindustries.com

Call: 0129-4902109/+91-8882490101

Powder Coating Plant Manufacturer

Paint Booth Manufacturers India

Aluminum Heat Treatment Furnace Manufacturers

Industrial Oven Manufacturer in India

High Temperature Furnace Manufacturers

Excavator Bucket Manufacturers in India

Excavator Pins and Bushes Manufacturer in India

Powder Coating Plant Manufacturer

Industrial Furnace Prices India

Air compressor Manufacturer Supplier

Industrial Furnace Manufacturer

Cabinet Type Shot Blasting Machine